|

|

|

| HART / Modbus

Gateway GT200-HT-RS Application in Sewage Treatment Plant

|

|

Keywords

|

| HART, Modbus, HART/Modbus, 4-20mA,

Rosemount, flowmeter

|

|

|

Background

|

Seven sewage treatment plants are

carrying out the renovation of the old project. Each factory has many ROSEMOUNT HART

instruments for collecting instantaneous flow and cumulative flow of wastewater in the

pipeline. Each instrument connects a PLC (HART master station) of the central control room.

PLC is responsible for real-time monitoring of the instantaneous flow and cumulative flow of

sewage in the pipeline to prevent excessive instantaneous flow of sewage in the pipeline

causing damage to the sewage treatment equipment and incomplete treatment to discharge the

polluted river. The central control room can control the flow rate of the sewage in time

according to the monitored instantaneous flow rate and cumulative flow rate of sewage in the

pipeline.

Requirements: Not only the instantaneous flow and accumulated flow collected by

the HART instrument should be transmitted to the central control room through the HART master

station PLC, but also transmitted to the EPA through the DCS (Modbus master station).

SST Automation's GT200-HT-RS can meet the

needs of customer!

|

|

|

System Composition

|

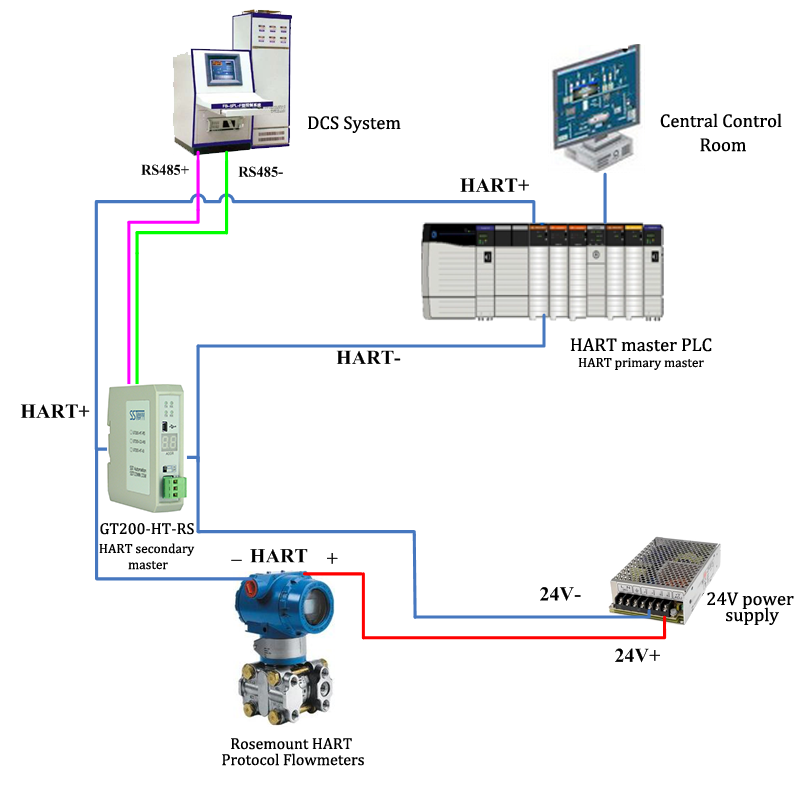

| The entire system consists of three

parts: on-site HART slave device, monitor system of central control room (HART master station

PLC system), and the EPA. The monitor system collects the instantaneous flow and cumulative

flow of the instrument through the PLC as the HART master station. The DCS system (Modbus

master station) collects the instrument flow through the GT200-HT-RS (at the HART side,

it's the second master station).

|

|

|

|

|

|

Summary

|

| GT200-HT-RS is used as the

HART secondary master station and the primary master station in parallel to collect HART meter

data. The "Diagnostics" function in the configuration software SST-HT-CFG helps the customer

check HART floating point values in the debug mode. Besides, the newly added support for HART

data segment mapping and high and low register swapping can only collect the required data and

meet the need to configure the data into a limited pre-defined registers, which greatly

facilitates on-site debugging and reduces the customer's acquisition on the DCS side.

|

|

|

|

California Office:

3200 E Guasti Rd, STE 100, Ontario, CA 91761

Tel: 844-606-2886 (US & Canada)

+1 (626) 899-6290

(International)

|

Asian Pacific Office:

6E, Bld 3, 518# Xinzhuan Rd, Songjiang District,

Shanghai 201612,

China

Tel: +86-18917828842

|

|

|

|