|

|

|

SST Automation

EtherNet/CAN Gateway GT200-MT-CA

Application in Sewage Treatment

|

|

Keywords

|

| CAN2.0A/CAN2.0B, CAN to Ethernet, CAN

communication monitoring, Sewage Treatment, CAN to Modbus TCP

|

|

Background

|

With the rapid development of the industry,

the discharge of industrial wastewater is increasing and the water pollution is getting worse, the

demand for sewage treatment is increasing now.

Filtration treatment and centrifugal separation are frequently used in various methods of sewage

treatment.

Centrifugal separation is used in this wastewater treatment case. Differential centrifugation is the

most widely used centrifugal separation technique. It is important whether the inverter can controls

the speed and torque accurately.

|

| System

functions

|

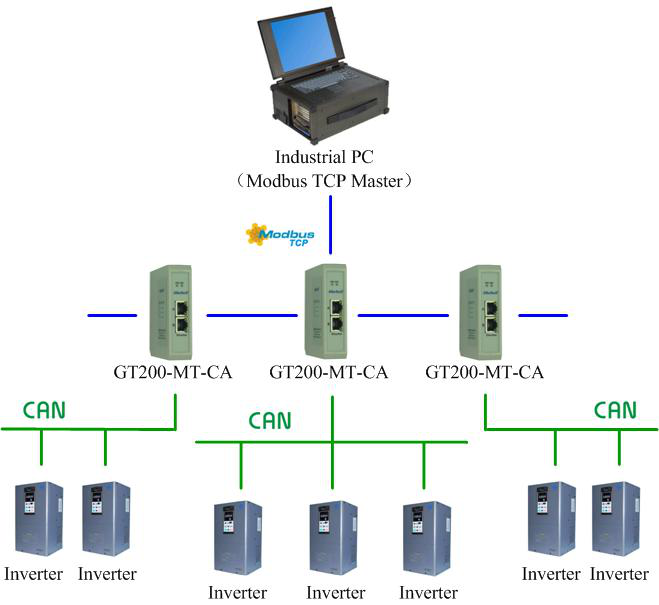

Using the gateway GT200-MT-CA to connect the CAN

interface of centrifuge inverter and then convert it to Modbus TCP protocol to connect with IPC

(support Modbus TCP protocol), to realize the centrifuge speed and torque parameters monitor and

control by IPC

Meanwhile,the sewage treatment plant covers a large area, the distribution of each centrifuge is

scattered and the wiring is tedious. The gateway GT200-MT-CA can solve those

problems through the cascade connection, which makes wiring easy, simple and save the cable and

switch costs.

|

|

| System

composition diagram

|

|

|

Summary

|

| The sewage treatment system uses SST

Automation

CAN to Modbus TCP gateway to achieve the communication between inverter and IPC. The gateway network

port used built-in switch, support cascade connection, saving cables, switches and costs. With the

powerful PC monitor software, users can easily debug with the inverter and use conveniently.

|

|

|

|

California Office:

3200 E Guasti Rd, STE 100, Ontario, CA 91761

Tel: 844-606-2886 (US & Canada)

+1 (626) 899-6290

(International)

|

Asian Pacific Office:

6E, Bld 3, 518# Xinzhuan Rd, Songjiang District,

Shanghai 201612,

China

Tel: +86-18917828842

|

|

|

|